MagPanel® is a strong, high quality, fire-resistant, mineral-based building material used to replace regular MgO boards, plywood, fiber cement panels, OSB and gypsum wallboards. It is an extremely versatile product for use with interior and exterior construction. It is made from bonding certain elements (including magnesium and oxygen) which results in an extremely strong cement-like material.

Expansive deposits of magnesium oxide can be found in China, Europe, and Canada. The great White Mountains in China have so much natural MgO, it is estimated there is enough to last another 800 years at today's rate of consumption. Thus, MagPanel® is an incredible building material with seemingly unlimited uses. It can be used in place of drywall, and some of the many applications include sub-flooring and tile backer, ceilings, walls, exteriors, soffits, sheathing, shaft-liner, bathtub enclosures, and exterior siding. When used for exterior projects it must be coated or protected from the elements.

MgO board is harder and stronger than drywall, and it is resistant to fire, insects, mold, mildew, and rot. It is sound and impact resistant, and has good insulating characteristics. It's noncombustible and non-toxic, has a receptive bonding surface, and contains no dangerous toxins like some other building materials. One exciting characteristic about Magnesium board is that it's lightweight while still being very, very strong. Therefore, a smaller amount of MgO board can do the same job (or better) as a greater amount of another material, such as sheetrock. And don't forget, because MgO board is so moisture-resistant, it lasts a very long time. The Great Wall of China is a perfect example of that!

Magpanel® can be sawed, drilled, router-shaped, scored and snapped, nailed, and painted. It's many uses in the construction field include fire-resistant materials for ceilings and walls in every type of construction including apartment complexes, theaters, airports, hospitals, and much more.

This amazingly versatile product also happens to be very green (environmentally friendly – not the color green). It has no ammonia, formaldehyde, benzene, silica, or asbestos, and it is completely safe for humans. It's a natural product that can be completely recycled, so it leaves a very small carbon footprint, and has no negative impact on landfills.

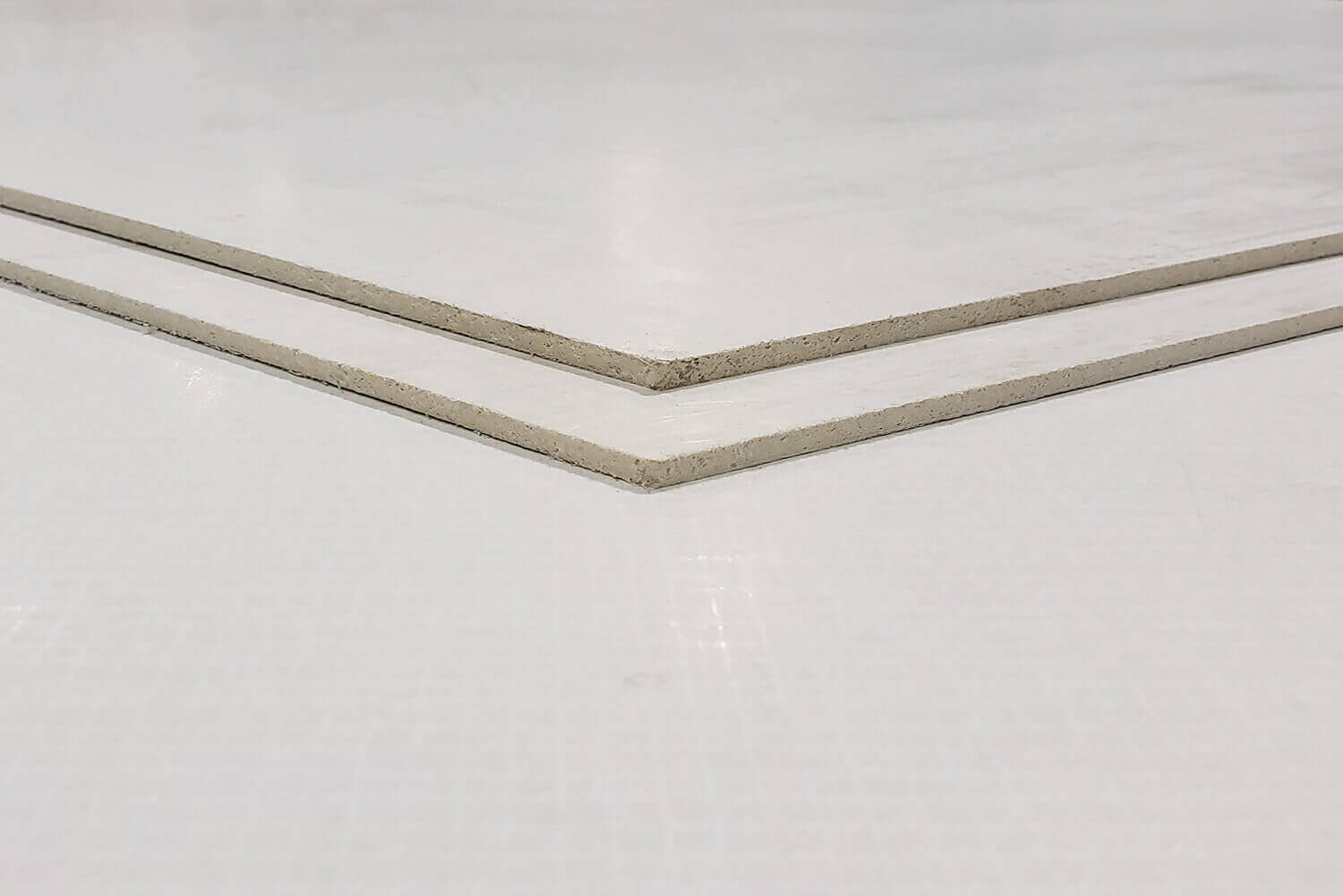

MagPanel® is available in a variety of sizes and thicknesses, it comes in a choice of basic colors and textures, and there are different grades and strengths to choose from, depending on the application. Because of its strength, thin boards can be used in place of thicker boards of another material.